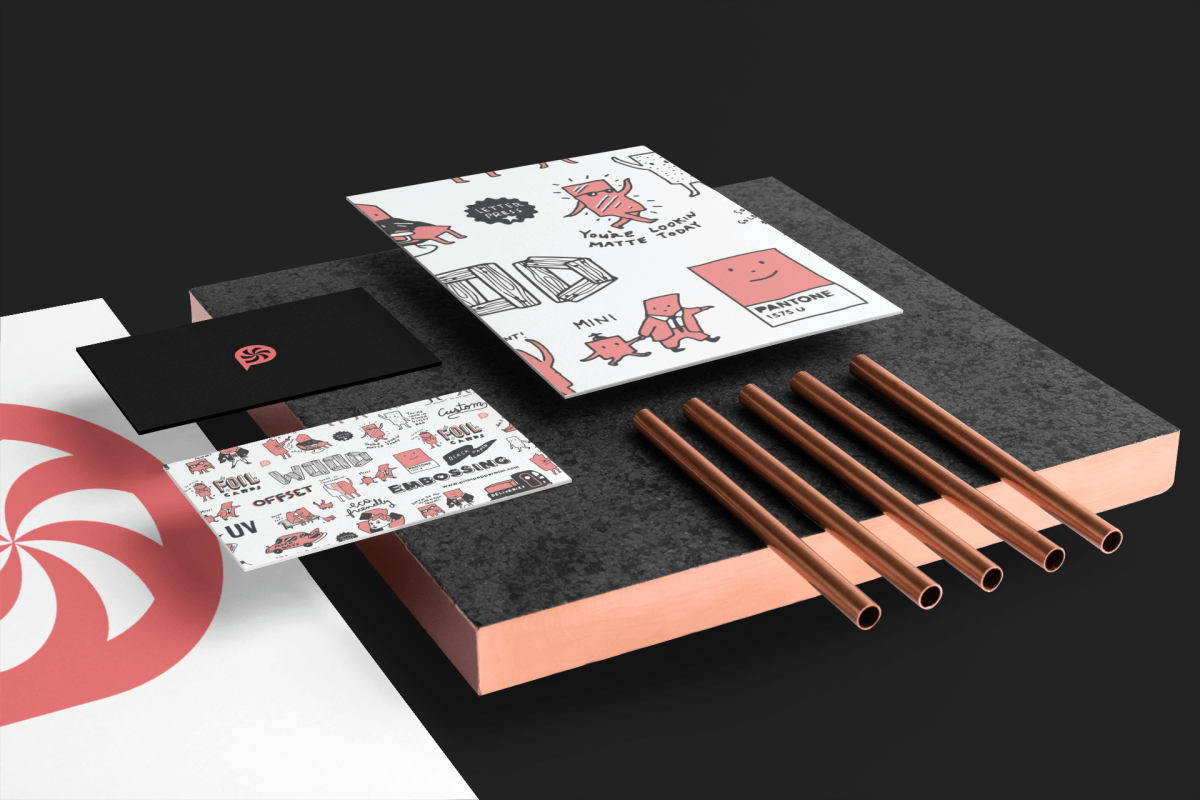

Luxury Business Cards Printed on Premium Paper with Endless Finishes.

-

Business Card Examples Pack

Regular price $9.00Regular priceUnit price / per -

Foil Business Cards

Regular price $49.00Regular priceUnit price / per -

Spot UV Business Cards

Regular price $49.00Regular priceUnit price / per -

Rounded Corner Business Cards

Regular price $69.00Regular priceUnit price / per

Popular Categories

-

Business Cards

Find the perfect paper, shape, and finish that speaks to you.

-

Custom Stickers

Stick your brand on anything with this fun marketing giveaway.

-

Stationery

Personalized stationery to match your brand and style.