Learn how to add Gold Foil to your Business Cards, Wedding Invitations, and Stickers like a Pro Graphic Designer!

Austin, from Print Peppermint, compares 6 of the best ways to add gold foil to your prints, including: hot foil stamping vs Pantone's metallic ink vs inline foil vs Scodix foil vs metallic foil papers vs DIY crafting.

We look at how to set up your files in Photoshop or any design software, including how to build a black and white mask file to deliver to your printer which will govern how foil is placed on your prints.

Transcription:

1

00:00:00,130 --> 00:00:03,762

So, you want to know how to add that bling-bling wow

effect to your business card,

2

00:00:03,762 --> 00:00:05,421

wedding invitation or sticker?

3

00:00:05,421 --> 00:00:11,391

Well, today, we're going to cover six different ways

that pro designers add gold foil to their prints,

4

00:00:11,391 --> 00:00:18,890

including hot foil, inline foil, Scodix foil,

ready-made metallic papers, Pantone metallic inks,

5

00:00:18,890 --> 00:00:20,280

and DIY crafting.

6

00:00:20,280 --> 00:00:24,220

We'll go over the pros and cons of each method, look,

at some design tips,

7

00:00:24,220 --> 00:00:29,570

and talk about how to set up your file in Photoshop or

your design software of choice.

8

00:00:29,570 --> 00:00:30,760

Let's get creative.

9

00:00:34,050 --> 00:00:36,910

♪ [music] ♪

10

00:00:36,910 --> 00:00:39,420

Howdy-do, internet folks,

Austin here with Print Peppermint.

11

00:00:39,420 --> 00:00:45,252

And today, we're going to talk about gold gold gold.

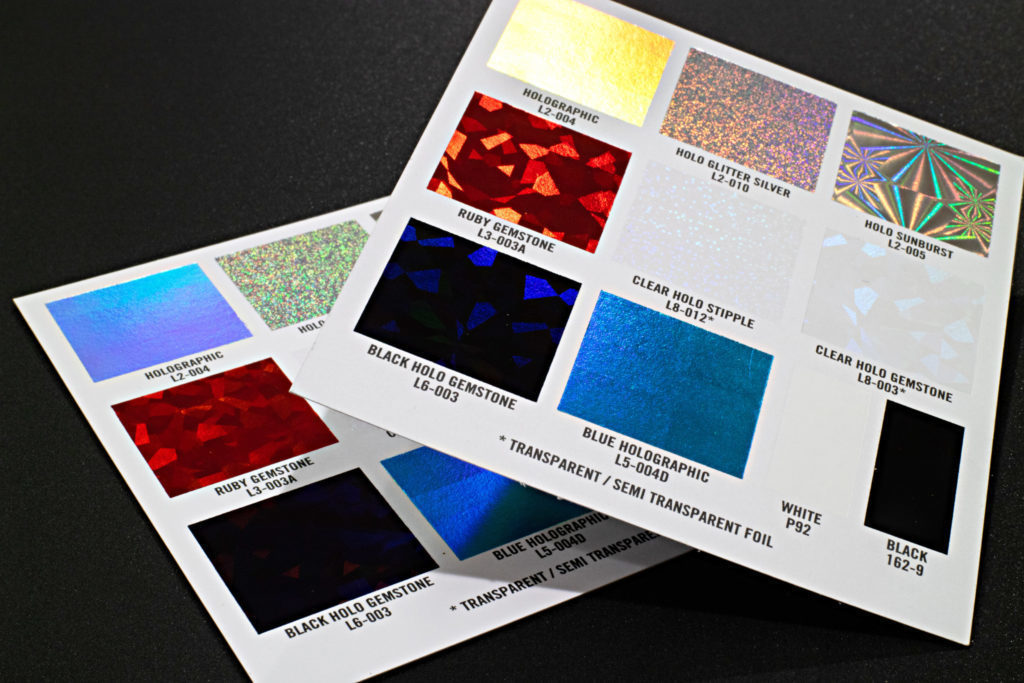

12

00:00:45,252 --> 00:00:50,810

Now, look, I originally started to script out a super

detailed video about the history of gold foil,

13

00:00:50,810 --> 00:00:54,120

the technical specs of the machines used to make foil.

14

00:00:54,120 --> 00:00:57,500

And, in the middle of it,

I realized it was going to be rather dense and

15

00:00:57,500 --> 00:00:58,860

probably very boring.

16

00:00:58,860 --> 00:01:03,245

So, instead, what we're going to talk about,

what I think designers care most about,

17

00:01:03,245 --> 00:01:08,257

is the luxurious aesthetic results that can be achieved

when using foil

18

00:01:08,257 --> 00:01:13,110

and how each production method might influence

the way you approach your design.

19

00:01:13,110 --> 00:01:18,320

We're going to cover quite a few topics today, so,

I will post chapter links in the description below so

20

00:01:18,320 --> 00:01:22,660

that you can easily jump to the part of the video

that's most relevant to you.

21

00:01:22,660 --> 00:01:27,740

As always, this video is not sponsored by any of the

manufacturers mentioned here today.

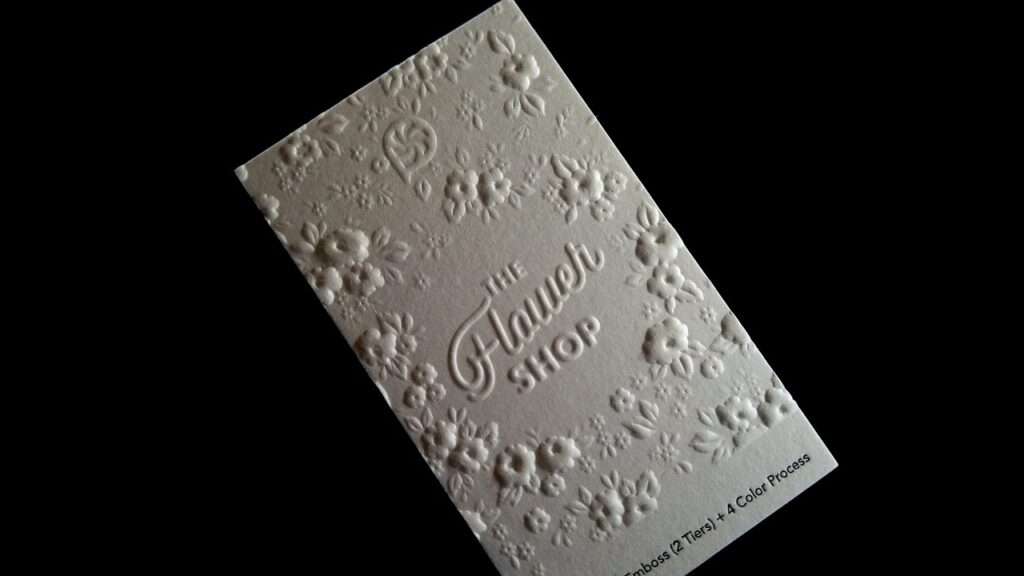

22

00:01:27,740 --> 00:01:31,950

These are products we buy with our own money and use on

our own projects.

23

00:01:31,950 --> 00:01:34,690

So, with that out of the way, let's get started.

24

00:01:34,690 --> 00:01:37,536

The first method we'll look at today is hot-foil

stamping,

25

00:01:37,536 --> 00:01:42,870

which is our method of choice here at Print Peppermint,

and has been the most popular way to add gold foil

26

00:01:42,870 --> 00:01:48,670

to your prints since it was first patented in 1892 by a

German named Ernst Oeser.

27

00:01:48,740 --> 00:01:53,540

According to Wikipedia,

hot stamping is a method of relief printing in which

28

00:01:53,540 --> 00:01:59,810

foil or pre-dried inks, aka pigment foils,

are transferred to a surface at high temperatures

29

00:01:59,810 --> 00:02:01,950

by applying pressure from a metal dye.

30

00:02:01,950 --> 00:02:08,660

Aside from it producing a sharp, crisp and detailed

impression, the primary benefit of hot foil in my eyes

31

00:02:08,660 --> 00:02:12,430

is the wide palette of colors

and the variety of available finishes.

32

00:02:12,430 --> 00:02:18,300

Don't expect to find hot wheels in every Pantone color,

but still, there is a very wide range.

33

00:02:18,300 --> 00:02:23,698

Unfortunately, for efficiency's sake, most online

printers, like MOO and VistaPrint, for example,

34

00:02:23,698 --> 00:02:25,909

only offer one shade of gold.

35

00:02:26,240 --> 00:02:31,536

At Print Peppermint, however, we offer five standard

gold colors and our full foil collection

36

00:02:31,536 --> 00:02:34,410

actually includes more than 100 shades of gold.

37

00:02:34,410 --> 00:02:39,800

We buy foils from a variety of manufacturers,

including KURZ, Crown Roll Leaf,

38

00:02:39,800 --> 00:02:42,059

Great Western, and Chenhui.

39

00:02:42,059 --> 00:02:47,230

We don't display this on our website though in order to

prevent our clients from having a gnarly case

40

00:02:47,230 --> 00:02:48,400

of choice paralysis.

41

00:02:48,400 --> 00:02:54,510

But it is this wide availability of colors that allows

us to hone in on the perfect shade of gold

42

00:02:54,510 --> 00:03:02,720

for every project, whether it's a classic yellow gold,

sophisticated rose gold, or a super regal aged gold.

43

00:03:02,720 --> 00:03:09,860

We break hot foil down into four different categories,

metallized, matte-metallized, holographic,

44

00:03:09,860 --> 00:03:11,280

and specialty effects.

45

00:03:11,280 --> 00:03:17,230

Metallized foils are the most common in circulation and

feature a highly reflective mirror-like appearance.

46

00:03:17,230 --> 00:03:22,570

This high reflection rate causes your gold foil to

appear super bright and super dark

47

00:03:22,570 --> 00:03:24,140

at certain viewing angles.

48

00:03:24,140 --> 00:03:28,020

This is, however, the nature of most metallic surfaces.

49

00:03:28,020 --> 00:03:32,550

Matte-metallized foils are similarly shiny but have a

more controlled shimmer,

50

00:03:32,550 --> 00:03:36,610

which allow for a more consistent

color even at extreme viewing angles.

51

00:03:36,610 --> 00:03:41,610

I find them to be more elegant and less in-your-face

than regular metallized foils.

52

00:03:41,610 --> 00:03:47,800

My personal favorite shade of gold is number 171M,

which is why it's featured first in our

53

00:03:47,800 --> 00:03:49,500

hot-foil swatch card.

54

00:03:49,500 --> 00:03:55,533

Holographic gold foils feature a gold foil base and a

holographic rainbow-like effect over top

55

00:03:55,533 --> 00:03:58,090

that jumps out at you at certain viewing angles.

56

00:03:58,090 --> 00:04:03,430

We have a handful of these foils in our collection

which vary in the amount of the rainbow holo effect

57

00:04:03,430 --> 00:04:08,590

and the direction in which the pattern travels,

with some being vertical and others diagonal.

58

00:04:08,590 --> 00:04:12,730

The last category of hot gold

foils we call "specialty effects."

59

00:04:12,730 --> 00:04:18,990

These foils feature a gold-foil base and a variety of

popular geometric patterns laid over top,

60

00:04:18,990 --> 00:04:23,750

such as glitter, prismatic,

pixelation, sunburst, and more.

61

00:04:23,750 --> 00:04:29,640

Although some of these foils can be rather gaudy,

when used creatively or limited to small elements that

62

00:04:29,640 --> 00:04:34,520

don't reveal the entirety of the pattern,

super groovy results can be achieved.

63

00:04:34,520 --> 00:04:38,760

Another benefit of hot-foil stamping

is its absolute consistency.

64

00:04:38,760 --> 00:04:40,740

What you see is what you get.

65

00:04:40,740 --> 00:04:46,870

Unlike ink, which can shift depending on the paper or

medium it's being printed on, hot foil does not.

66

00:04:46,870 --> 00:04:51,495

The color you choose from our foil swatch card will be

the identical foil color that

67

00:04:51,495 --> 00:04:53,970

lays down on top of your printed piece.

68

00:04:53,970 --> 00:04:59,900

And because most hot foils are solid or opaque,

they can be used to express light text

69

00:04:59,900 --> 00:05:06,305

or light elements on top of dark cardstock,

like this light gold on serial ultra black, shown here.

70

00:05:06,305 --> 00:05:08,305

♪ [music] ♪

71

00:05:12,120 --> 00:05:17,820

This is quite useful because offset inks are somewhat

translucent and when printed on non-white papers,

72

00:05:17,820 --> 00:05:24,270

allow a lot of the paper to show through resulting in

color shifting and lowered contrast or visibility.

73

00:05:24,270 --> 00:05:30,124

To combat this, we often use Pantone metallic inks,

like number 871C, shown here,

74

00:05:30,124 --> 00:05:34,287

which feature a silver additive that reduces

the translucency of the color,

75

00:05:34,287 --> 00:05:37,335

making it easier to see on darker cardstocks.

76

00:05:37,444 --> 00:05:41,384

We will talk more about Pantone

metallic inks later in the video.

77

00:05:41,670 --> 00:05:47,590

Many print shops often choose to use silk screen

printing to get light colors on dark papers because

78

00:05:47,590 --> 00:05:49,980

silk screen inks are mostly opaque.

79

00:05:49,980 --> 00:05:56,140

This can give great results but requires an entirely

different type of press and a tedious setup process

80

00:05:56,140 --> 00:06:01,040

that often makes it not viable for short-run projects

like a single set of business cards.

81

00:06:01,040 --> 00:06:05,310

Another benefit of hot-foil stamping is that it can be

paired with embossing,

82

00:06:05,310 --> 00:06:08,990

sometimes called foil embossing

or combination stamping.

83

00:06:08,990 --> 00:06:14,860

This means that in one pass of the press you can give

your logo a raised up dimensional feel and stamp it

84

00:06:14,860 --> 00:06:16,770

with gold foil at the same time.

85

00:06:16,770 --> 00:06:21,466

This is called a registered embossing because the

raised element and the foil

86

00:06:21,466 --> 00:06:23,470

are in perfect alignment with each other.

87

00:06:23,470 --> 00:06:28,032

The opposite of this is called blind embossing in which

the raised element stands alone

88

00:06:28,032 --> 00:06:30,456

with no assistance from ink or foil.

89

00:06:30,456 --> 00:06:36,849

A raised gold foil effect can also be achieved using a

Scodix finisher but there are some key differences

90

00:06:36,849 --> 00:06:41,245

when compared to hot foil,

which we will cover a bit later in the video.

91

00:06:41,280 --> 00:06:45,164

Another benefit of hot foil,

in our print shop at least,

92

00:06:45,164 --> 00:06:49,248

is that it can be ordered in combination with any other

print finish, including die cutting,

93

00:06:49,248 --> 00:06:51,248

spot UV, letter press, and more.

94

00:06:51,623 --> 00:06:56,840

We can even foil stamp on the edges of any printed

piece as long as the corners are not rounded.

95

00:06:56,840 --> 00:07:02,960

Please note, we do not recommend stamping foil over

spot UV or spot UV over foil.

96

00:07:02,960 --> 00:07:09,480

We do, however, recommend ordering multiple foil colors

and they can be stamped one over the other resulting

97

00:07:09,480 --> 00:07:12,630

in super exciting design possibilities.

98

00:07:12,630 --> 00:07:18,000

Another interesting feature of hot foil is that it can

be stamped onto nearly any type of material,

99

00:07:18,000 --> 00:07:21,742

including paper, leather, wood, and even plastic,

100

00:07:21,742 --> 00:07:25,084

as shown here in this translucent gold

foil business card.

101

00:07:25,430 --> 00:07:30,792

The last feature of hot foil I'd like to talk about and

probably the most relevant in today's world

102

00:07:30,792 --> 00:07:33,791

is the fact that it is environmentally friendly.

103

00:07:33,970 --> 00:07:40,750

According to two studies done by Georgia Tech and the

Foil & Specialty Effects Association, they showed that,

104

00:07:40,750 --> 00:07:47,020

when stamped on uncoated paper,

hot foil is biodegradable and can be recycled.

105

00:07:47,020 --> 00:07:53,540

Foil stamping is an entirely dry process which involves

no inks, solvents, or vapors and, therefore

106

00:07:53,540 --> 00:07:58,460

poses no harm to the environment,

a powerful claim that Pantone metallic inks

107

00:07:58,460 --> 00:08:01,110

and Scodix finishers are unable to match.

108

00:08:01,110 --> 00:08:04,320

Now, let's talk about some of

the cons of hot-foil stamping.

109

00:08:04,320 --> 00:08:08,220

For starters, it's sort of

expensive and kind of time-consuming.

110

00:08:08,220 --> 00:08:09,350

Let me explain.

111

00:08:09,350 --> 00:08:13,160

Foil is typically charged per color per location.

112

00:08:13,160 --> 00:08:19,450

So, if you wanted gold and silver foil on the front and

back of your piece, that would be four total locations.

113

00:08:19,450 --> 00:08:25,620

If the print shop charges $50 per location,

4 times 50 is a total of $200,

114

00:08:25,620 --> 00:08:29,200

not including any dye charges or

the cost of paper and ink.

115

00:08:29,200 --> 00:08:33,660

You see, for each location,

a custom metal dye has to be molded and then attached

116

00:08:33,660 --> 00:08:34,420

to the press.

117

00:08:34,420 --> 00:08:38,340

Many print shops don't have the in-house capabilities

to produce foil dyes,

118

00:08:38,340 --> 00:08:41,220

which means they have to be ordered from a third party.

119

00:08:41,220 --> 00:08:43,430

This takes time and adds cost.

120

00:08:43,430 --> 00:08:49,690

Another downside to hot foil is that it isn't always

suitable for large-coverage surface areas as air can

121

00:08:49,690 --> 00:08:53,530

get trapped underneath the foil and prevent it from

adhering to your paper.

122

00:08:53,530 --> 00:08:59,510

One way to get around that though is by employing

ready-made metallic gold-foil papers, like this one,

123

00:08:59,510 --> 00:09:04,190

which, as you can see,

have a full-coverage gold effect already on the paper.

124

00:09:04,190 --> 00:09:07,240

We'll talk a little bit more

about these later in the video.

125

00:09:07,240 --> 00:09:11,680

Another limitation of hot-foil stamping is that

gradients are not possible.

126

00:09:11,680 --> 00:09:16,440

Similar to letterpress printing,

your foil will either be on or off.

127

00:09:16,440 --> 00:09:21,880

So, if your logo has a whole lot of shading going on,

like this one does, your artwork will likely need to be

128

00:09:21,880 --> 00:09:25,490

simplified in order to work

well with hot-foil stamping.

129

00:09:25,490 --> 00:09:30,990

Some designers get around that though by using a

crosshatch or dot pattern for shading like we did

130

00:09:30,990 --> 00:09:36,395

in our letterpress paper samples bundle,

which you can view here by clicking the link above.

131

00:09:37,960 --> 00:09:42,714

Lastly, it is also worth mentioning that there are some

specialty foils that do

132

00:09:42,714 --> 00:09:47,191

gradate from one color to another

but the choice is rather limited,

133

00:09:47,191 --> 00:09:51,169

making it quite difficult to find a perfect foil for

every project.

134

00:09:51,169 --> 00:09:55,900

Now let's look at some tips and tricks to help you get

the most out of using hot foil for your

135

00:09:55,900 --> 00:10:01,724

next design project, including how to set up your file

in Photoshop or your design software of choice.

136

00:10:02,090 --> 00:10:08,858

So, one question we get asked a whole lot is,

"What type size should my font or text be

137

00:10:08,858 --> 00:10:11,834

if we're going to use hot-foil?"

138

00:10:12,550 --> 00:10:17,101

The answer to that question isn't always perfectly

clear but many printers will recommend

139

00:10:17,101 --> 00:10:19,383

a minimum type size of 8 points.

140

00:10:19,383 --> 00:10:23,040

This can vary though,

depending on the font face you're using,

141

00:10:23,040 --> 00:10:27,040

as many modern fonts do not

adhere to the same sizing standard.

142

00:10:27,040 --> 00:10:32,726

Although one of its strengths is precision and detail,

it's important to note that your logo or text

143

00:10:32,726 --> 00:10:37,788

may appear bolder or thicker when foil-stamped,

as opposed to ink-printed.

144

00:10:37,788 --> 00:10:43,300

The most important thing to remember when designing for

foil is to leave enough breathing room or negative

145

00:10:43,300 --> 00:10:46,940

space in between design elements and font characters.

146

00:10:46,940 --> 00:10:50,662

This helps prevent the foil from merging, like this.

147

00:10:54,890 --> 00:11:01,174

We recommend a minimum space of 0.3 millimeters,

or .012 inches, between elements.

148

00:11:01,174 --> 00:11:07,140

We also recommend a minimum line width of 0.1

millimeters, or .004 inches.

149

00:11:07,140 --> 00:11:13,050

So, if your scripty font has super thin curves,

do expect a little bit of loss in detail,

150

00:11:13,050 --> 00:11:17,160

which isn't always bad and is part

of the nature of foil stamping.

151

00:11:17,160 --> 00:11:21,040

Not only is extra kerning,

meaning the space between characters,

152

00:11:21,040 --> 00:11:27,630

a great principle of basic typography design but it

will also aid in the avoidance of foil merging.

153

00:11:27,630 --> 00:11:32,960

Now let's talk about mask files and how to set them up

in Photoshop or, in my case, Affinity Designer.

154

00:11:32,960 --> 00:11:38,640

We made an entire video about how to set up mask files

for spot UV, which I'll link to up here,

155

00:11:38,640 --> 00:11:41,900

but the principle is exactly

the same for foil stamping.

156

00:11:41,900 --> 00:11:43,680

So, what the [beep] is a mask file?

157

00:11:43,680 --> 00:11:50,060

A mask file is a black-and-white PDF in which black has

the value K equals 100%.

158

00:11:50,060 --> 00:11:55,010

Anything shown in black will get foiled and anything in

white will not.

159

00:11:55,010 --> 00:11:56,060

Simple, right?

160

00:11:56,060 --> 00:12:02,000

It is preferable to create mask files in vector format,

using a vector design software like Adobe Illustrator

161

00:12:02,000 --> 00:12:05,338

or CorelDRAW, but raster mask files can also work,

162

00:12:05,338 --> 00:12:09,051

as long as they have a minimum resolution

of 300 dots per inch.

163

00:12:09,340 --> 00:12:13,948

If you find this confusing or just need a little help,

I welcome you to send us your design files

164

00:12:13,948 --> 00:12:18,200

and we'll create your mask files for you,

assuming they aren't overly intricate.

165

00:12:18,200 --> 00:12:23,010

The second method of producing gold foil I'd like to

talk about today is Scodix finishers.

166

00:12:23,010 --> 00:12:27,820

The Scodix machine is a near-line digital finishing

system that makes low-volume print runs,

167

00:12:27,820 --> 00:12:30,063

even one-offs, economically-viable.

168

00:12:30,063 --> 00:12:33,739

In addition, it opens up an entire new world of

variability,

169

00:12:33,739 --> 00:12:38,710

especially when it comes to personalizing

printed pieces with foil or spot UV.

170

00:12:38,710 --> 00:12:43,170

Unlike traditional foil stamping,

it does not require the use of a metal dye,

171

00:12:43,170 --> 00:12:46,930

helping print shops keep all

their production in-house and efficient.

172

00:12:46,930 --> 00:12:52,920

This is one of the chief technologies used by moo.com

that allows them to offer unique print finishes

173

00:12:52,920 --> 00:12:56,000

at reasonably cheap prices with quick turnarounds.

174

00:12:56,000 --> 00:12:58,920

Let's talk about some of the benefits of Scodix foil.

175

00:12:58,920 --> 00:13:02,547

Scodix foil has a raised bubbly-like appearance that

measures in height

176

00:13:02,547 --> 00:13:06,560

to approximately 50 microns

or .002 inches.

177

00:13:06,560 --> 00:13:12,000

Many designers find this embossed or sculpted

appearance desirable, but do note that,

178

00:13:12,000 --> 00:13:16,801

compared to hot foil, it does not always perform well

on small elements with fine detail

179

00:13:16,801 --> 00:13:19,131

like 2 or 4-point text.

180

00:13:19,131 --> 00:13:22,900

And with the Scodix finisher,

although the foil is typically raised,

181

00:13:22,900 --> 00:13:27,550

especially when buying online,

the foil can be produced at a height as low

182

00:13:27,550 --> 00:13:29,930

as 5 microns, which is pretty darn flat.

183

00:13:29,930 --> 00:13:35,850

Similar to hot foils, Scodix foil is not well suited

for large solid surface areas.

184

00:13:35,850 --> 00:13:39,638

A general guideline is to keep coverage under 30%.

185

00:13:39,638 --> 00:13:44,200

Because the Scodix is a digital machine,

this makes it perfect for projects requiring

186

00:13:44,200 --> 00:13:49,290

variable data, for example,

the direct-mail postcard in which each client's name

187

00:13:49,290 --> 00:13:51,150

could be printed in gold.

188

00:13:51,150 --> 00:13:54,819

Scodix partners with a number of foil manufacturers

from around the world

189

00:13:54,819 --> 00:13:58,920

and is available in all of the primary colors

and noble metals.

190

00:13:58,920 --> 00:14:04,730

It also comes in many holographic colors like this

silver holographic effect shown here.

191

00:14:04,730 --> 00:14:10,510

Although Scodix claims that more colors are constantly

being added to the foil manufacturer's offerings,

192

00:14:10,510 --> 00:14:16,930

I think it's safe to assume that hot foil offers a

wider pallet of colors and specialty finishes.

193

00:14:16,930 --> 00:14:21,140

Another benefit of Scodix foil is that,

because it is an inline process,

194

00:14:21,140 --> 00:14:25,140

it is rather quick to turn around and less costly.

195

00:14:25,140 --> 00:14:31,113

Although this translates to less cost for the end

customer, the startup costs of a half million dollars

196

00:14:31,113 --> 00:14:35,130

for a Scodix machine make it out of reach for many

mom-and-pop print shops.

197

00:14:35,130 --> 00:14:38,400

Now, let's talk about some of the cons of Scodix foil.

198

00:14:38,400 --> 00:14:45,060

The problem I find most troublesome is that it's not

compatible with most luxury uncoated paper stocks.

199

00:14:45,060 --> 00:14:51,820

Most online printers will force you to buy Scodix foil

on a matt-coated or matt-laminated paper stock.

200

00:14:51,820 --> 00:14:57,340

Because we're real paper freaks here at Print

Peppermint, this motivates me to consistently recommend

201

00:14:57,340 --> 00:14:59,990

hot foil over Scodix foil any day of the week.

202

00:14:59,990 --> 00:15:06,650

Another limitation to Scodix foil is that it can't

bleed, meaning it can't run off the edge of your paper

203

00:15:06,650 --> 00:15:07,890

whereas hot foil can.

204

00:15:07,890 --> 00:15:14,260

Now that we've talked about the pros and cons of Scodix

raised foil, let's talk about how to set up your files.

205

00:15:14,260 --> 00:15:18,640

Essentially, the process is exactly the

same as with hot-foil stamping.

206

00:15:18,640 --> 00:15:22,960

A black-and-white mask file is required and vector

format is preferred.

207

00:15:22,960 --> 00:15:28,700

If you missed that chapter earlier in the video,

I'll post the link here now.

208

00:15:28,700 --> 00:15:32,946

The main thing to remember when designing for Scodix

foil is to pay attention to the

209

00:15:32,946 --> 00:15:34,422

sizing of your elements.

210

00:15:34,422 --> 00:15:38,269

Where hot foil shops will recommend a minimum of

8-point fonts,

211

00:15:38,269 --> 00:15:44,420

Scodix foil providers often recommend a

minimum of 10, or even 12 points, in some cases.

212

00:15:44,420 --> 00:15:49,120

And please remember that the bubbly dimensional

appearance can make smaller elements

213

00:15:49,120 --> 00:15:50,820

appear less detailed.

214

00:15:50,820 --> 00:15:57,160

Now I'd like to talk about cold foil,

sometimes referred to as inline foil or aqua foil,

215

00:15:57,160 --> 00:16:03,430

which involves printing your four-color process inks on

top of a silver foil-like substrate.

216

00:16:03,430 --> 00:16:09,380

Since digital and offset inks are partially

transparent, this allows the silver foil-like substrate

217

00:16:09,380 --> 00:16:14,160

to shine up through your inks,

creating a wide variety of metallic colors,

218

00:16:14,160 --> 00:16:17,050

including gradients and even photographs.

219

00:16:17,050 --> 00:16:22,690

This method was made popular by vistaprint.com under

the name "foil accents."

220

00:16:22,690 --> 00:16:28,200

One of the primary benefits of cold foil is that,

as a designer, you can determine the color of your

221

00:16:28,200 --> 00:16:33,070

metallic areas via the CMYK color

code present in your design file.

222

00:16:33,070 --> 00:16:37,310

The downside to this though is that it can be quite

difficult in predicting how your

223

00:16:37,310 --> 00:16:40,230

on-screen metallic colors will look after printing.

224

00:16:40,230 --> 00:16:44,140

In our experimentation,

we found that the lighter your CMYK colors are,

225

00:16:44,140 --> 00:16:48,450

the more metallic they will appear after printing,

and vice versa.

226

00:16:48,450 --> 00:16:52,827

To help our designers and clients,

we've created a cold-foil swatch card

227

00:16:52,827 --> 00:16:57,483

with a list of optimized CMYK values and

showing what they look like

228

00:16:57,483 --> 00:16:59,878

with and without a spot gloss treatment.

229

00:16:59,878 --> 00:17:06,800

Hot tip, the spot gloss coating does enhance the

metallic effect making cold foil appear even that much

230

00:17:06,800 --> 00:17:09,231

closer to traditional hot-foil stamping.

231

00:17:09,420 --> 00:17:14,260

And similar to Scodix foil,

cold foil does not require the use of a metal dye,

232

00:17:14,260 --> 00:17:18,830

making it less time-consuming to produce and less

expensive for the consumer.

233

00:17:18,830 --> 00:17:24,290

Although cold foil comes very close,

I still personally prefer the look of hot-foil stamping

234

00:17:24,290 --> 00:17:29,780

as it will always have a slight debossed impression due

to the pressure of the metal dye.

235

00:17:29,780 --> 00:17:33,720

Another thing to remember is that cold-foil,

similar to Scodix foil,

236

00:17:33,720 --> 00:17:39,330

is mostly limited to matte-coated papers,

making it a deal-breaker for many of my projects.

237

00:17:39,330 --> 00:17:44,110

I won't waste any of your time going over file setup as

it is exactly the same as Scodix foil

238

00:17:44,110 --> 00:17:48,688

or traditional hot foil but I will link to that chapter

here, in case you missed it.

239

00:17:50,855 --> 00:17:54,939

Now let's talk about Pantone metallic inks,

when to use them, and how they compare

240

00:17:54,939 --> 00:17:57,189

to the other methods we've already talked about.

241

00:17:57,189 --> 00:18:02,331

For starters, it's important to note that Pantone's

metallic ink series was initially developed

242

00:18:02,331 --> 00:18:03,524

for coated papers.

243

00:18:03,524 --> 00:18:09,140

But with some experimentation,

it can yield great results on uncoated stocks as well,

244

00:18:09,140 --> 00:18:14,820

like we used in our letterpress paper sample bundle,

which you can check out here.

245

00:18:14,820 --> 00:18:20,230

Pantone metallic inks are made with an advanced

aluminum pigment that makes them much more opaque

246

00:18:20,230 --> 00:18:21,760

than offset inks.

247

00:18:21,760 --> 00:18:28,233

Which is why we like to use them to print on colored

cardboard like this Sirio Ultra Back from Fedrigoni.

248

00:18:29,390 --> 00:18:33,365

At Print Peppermint, we're currently working on an

all-black paper samples bundle,

249

00:18:33,365 --> 00:18:38,970

in which one side of the piece will be

printed with Pantone metallic 877 and the other side

250

00:18:38,970 --> 00:18:43,610

will feature a silver-foil stamp so designers can

easily compare the two.

251

00:18:43,610 --> 00:18:47,805

The main thing to remember is that hot foil is an

opaque sheet that sits on top of

252

00:18:48,210 --> 00:18:53,259

the fibers of your paper, whereas Pantone metallic inks

are absorbed into the fibers of the paper

253

00:18:53,259 --> 00:18:56,500

and will allow some of the paper to show through.

254

00:18:56,500 --> 00:19:01,511

For many designers, this is a desirable effect as it

subdues the metallic shimmer,

255

00:19:01,511 --> 00:19:03,926

making it more elegant and less flashy.

256

00:19:04,170 --> 00:19:08,020

Some would say it appears

even more handmade or organic.

257

00:19:08,020 --> 00:19:13,529

In terms of overall production time, metallic inks

take about the same time as hot-foil stamping,

258

00:19:13,529 --> 00:19:19,139

making them a somewhat less affordable option when

compared to Scodix foil or cold foil.

259

00:19:19,200 --> 00:19:23,850

And again, file setup is exactly the same as the other

methods mentioned here today, so

260

00:19:23,850 --> 00:19:26,440

I will link to that chapter again right here.

261

00:19:27,540 --> 00:19:32,630

Now let's talk about ready-made gold-foil paper and

other metallic sheets.

262

00:19:32,630 --> 00:19:35,897

There are a wide variety of manufacturers making

metallic papers,

263

00:19:35,897 --> 00:19:38,418

many of which you can find easily on Amazon.

264

00:19:38,418 --> 00:19:42,460

But in terms of quality,

I can only speak for the ones we use regularly,

265

00:19:42,460 --> 00:19:46,080

which typically come from larger,

more established paper mills,

266

00:19:46,080 --> 00:19:51,337

like the Curious collection from Arjowiggins,

Splendorlux Mirror from Fedrigoni,

267

00:19:51,337 --> 00:19:55,780

STARDREAM from Cordenons, or Gmund Gold

from Gmund.

268

00:19:55,780 --> 00:20:01,470

The primary benefit to using ready-made metallic papers

is that no foil stamping is required.

269

00:20:01,470 --> 00:20:07,210

You can simply print your company name or logo in a

deep black ink and you're ready to go.

270

00:20:07,210 --> 00:20:12,230

Many of these papers have unique textures already built

into the paper, which aren't possible to achieve

271

00:20:12,230 --> 00:20:14,910

with the other methods we've talked about today.

272

00:20:14,910 --> 00:20:21,030

These papers can also be die cut, scored,

and folded without any detriment to the metallic area.

273

00:20:21,030 --> 00:20:26,330

Hot foil, for example,

might crack or fall off if scored or folded.

274

00:20:26,330 --> 00:20:30,433

In terms of design considerations for metallic paper,

the biggest limitation is

275

00:20:30,433 --> 00:20:34,070

that you need to keep your printed inks

reasonably dark.

276

00:20:34,070 --> 00:20:38,520

Since the paper is heavily colored,

any ink that gets laid down will shift

277

00:20:38,520 --> 00:20:40,420

and darken significantly.

278

00:20:40,420 --> 00:20:45,950

One way to get around this would be to actually use

hot-foil stamping on top of the metallic sheet.

279

00:20:45,950 --> 00:20:50,370

This would give you zero color shift and absolute

contrast and legibility.

280

00:20:50,370 --> 00:20:56,640

Do keep in mind, we also have pigment foils that,

although applied in the same way as metallic foil,

281

00:20:56,640 --> 00:20:59,870

have a flat ink-like appearance after stamping.

282

00:20:59,870 --> 00:21:04,090

Okay, I know I promised six different ways to add gold

foil to your prints.

283

00:21:04,090 --> 00:21:09,100

But since DIY crafting and scrapbooking is really out

of my realm of expertise,

284

00:21:09,100 --> 00:21:15,090

I'm going to link to this awesome video from Jennifer

McGuire Ink's channel in which she goes over five

285

00:21:15,090 --> 00:21:21,900

different ways to add gold foil to your prints by hand

using a combination of glue, deco foil,

286

00:21:21,900 --> 00:21:23,220

stamps, and tape.

287

00:21:23,220 --> 00:21:25,050

Well, that's enough out of me for today.

288

00:21:25,050 --> 00:21:26,680

I hope you enjoyed what you saw.

289

00:21:26,680 --> 00:21:31,980

And if you did, please consider subscribing by clicking

the bell in the bottom right-hand corner.

290

00:21:31,980 --> 00:21:36,290

We will be posting a similar video about gold-foil

stickers in the coming weeks,

291

00:21:36,290 --> 00:21:39,600

and that way you'll get notified

the moment that it's uploaded.

292

00:21:39,600 --> 00:21:42,648

Thanks again for watching and we'll

catch you in the next one.

293

00:21:46,800 --> 00:21:49,700

♪ [music] ♪